Mubashir Hasan

PhD, Mechanical Engineering

Reliability & Asset Integrity | CFD & Structural Analysis

mubashirhasan333@gmail.com

(918) 851-4492

About

I am a Mechanical Engineer with broad experience spanning project execution, asset integrity, manufacturing, and research. My expertise includes fluid mechanics, computational simulations (CFD), 3D modeling, and reliability-centered maintenance, with practical application of ASME, API, ISO, and OREDA standards to ensure safe and efficient operations in the oil and gas and energy sectors.

Earlier in my career, I served as a Project Engineer, managing multidisciplinary teams, coordinating project schedules, and leading equipment installation and commissioning activities strengthening my leadership, communication, and problem-solving skills in dynamic, fast-paced environments. My exposure to manufacturing and quality control environments has provided me with a strong understanding of industrial processes, precision standards, and workflow optimization. At The University of Tulsa, my graduate research on erosion damage in pipeline equipment integrated experimental investigation, computational simulations, data analysis, and mathematical modeling. This experience enhanced my proficiency in CFD (ANSYS Fluent), 3D modeling (SolidWorks), and scientific programming (Excel VBA and Python), while fostering a solid foundation in analytical thinking and system optimization.

Recognized for being a motivated and adaptable professional, I am passionate about continuous learning and committed to delivering innovative, high-quality engineering solutions that enhance performance, reliability, and sustainability.

Education

The University of Tulsa — Tulsa, OK

M.S. in Mechanical Engineering

CGPA: 3.91

University of Engineering & Technology — Lahore, Pakistan

B.S. in Mechanical Engineering

CGPA: 3.35

Experience

Velosi Asset Integrity & Safety — Lahore, Pakistan

Assistant Mechanical Engineer

- Developed asset registers and maintenance plans for mechanical systems.

- Applied Failure Modes Effects and Criticality Analysis (FMECA) using OREDA data for risk prioritization.

- Designed Preventive Maintenance Routines (PMRs) to improve system uptime and safety compliance.

The Erectors — Lahore, Pakistan

Project Engineer

- Led mechanical erection of Tea Whitener Plant at Shakarganj Food Products Ltd using multiple project teams, P&IDs, plant layouts, and 3D drawings.

- Resolved field issues collaboratively with clients and contractors to meet commissioning deadlines.

Projects

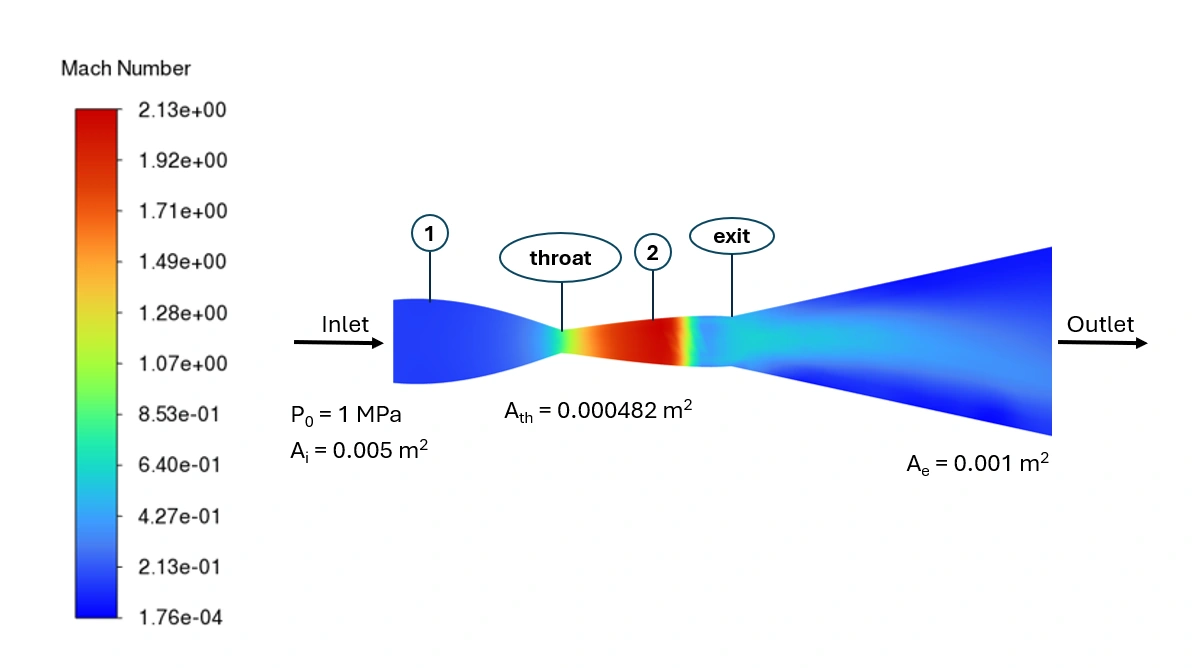

Gas Dynamics – CFD Simulation Project

Course Project

Performed analytical and CFD analysis of compressible gas flow through a converging-diverging nozzle using ANSYS Fluent. Compared inviscid and Spalart-Allmaras models under varying back pressures to study shock formation, Mach number distribution, and flow convergence, strengthening skills in turbulence modeling and compressible flow analysis.

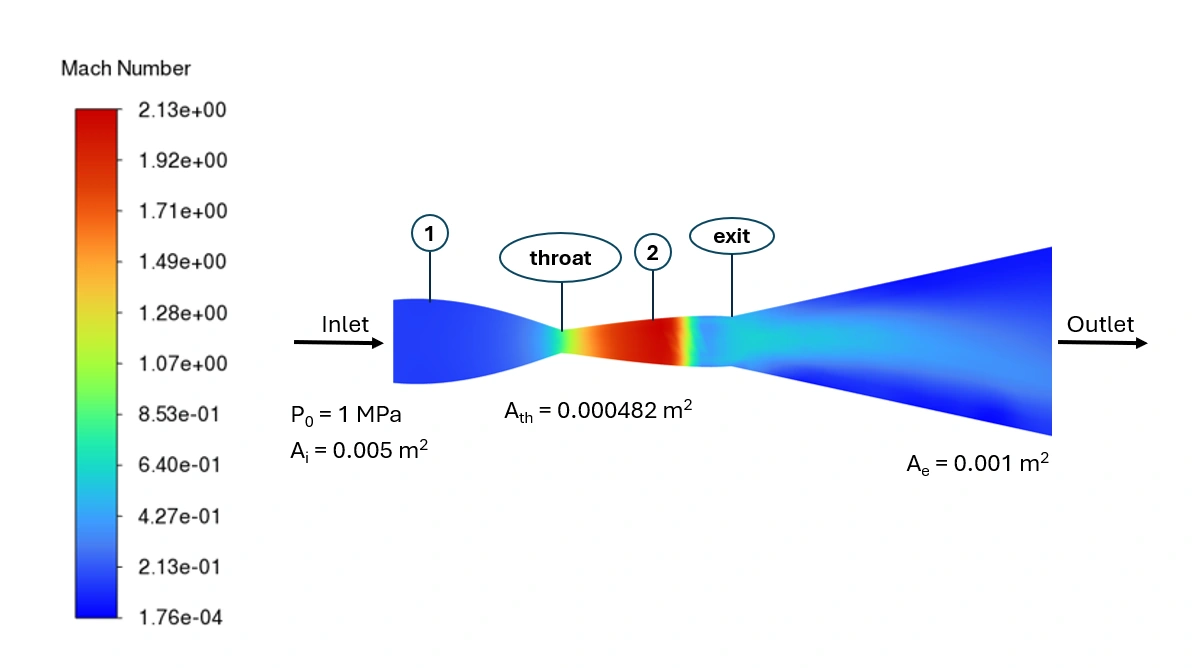

Gas Dynamics – CFD Simulation Project

Course Project

Performed analytical and CFD analysis of compressible gas flow through a converging-diverging nozzle using ANSYS Fluent. Compared inviscid and Spalart-Allmaras models under varying back pressures to study shock formation, Mach number distribution, and flow convergence, strengthening skills in turbulence modeling and compressible flow analysis.

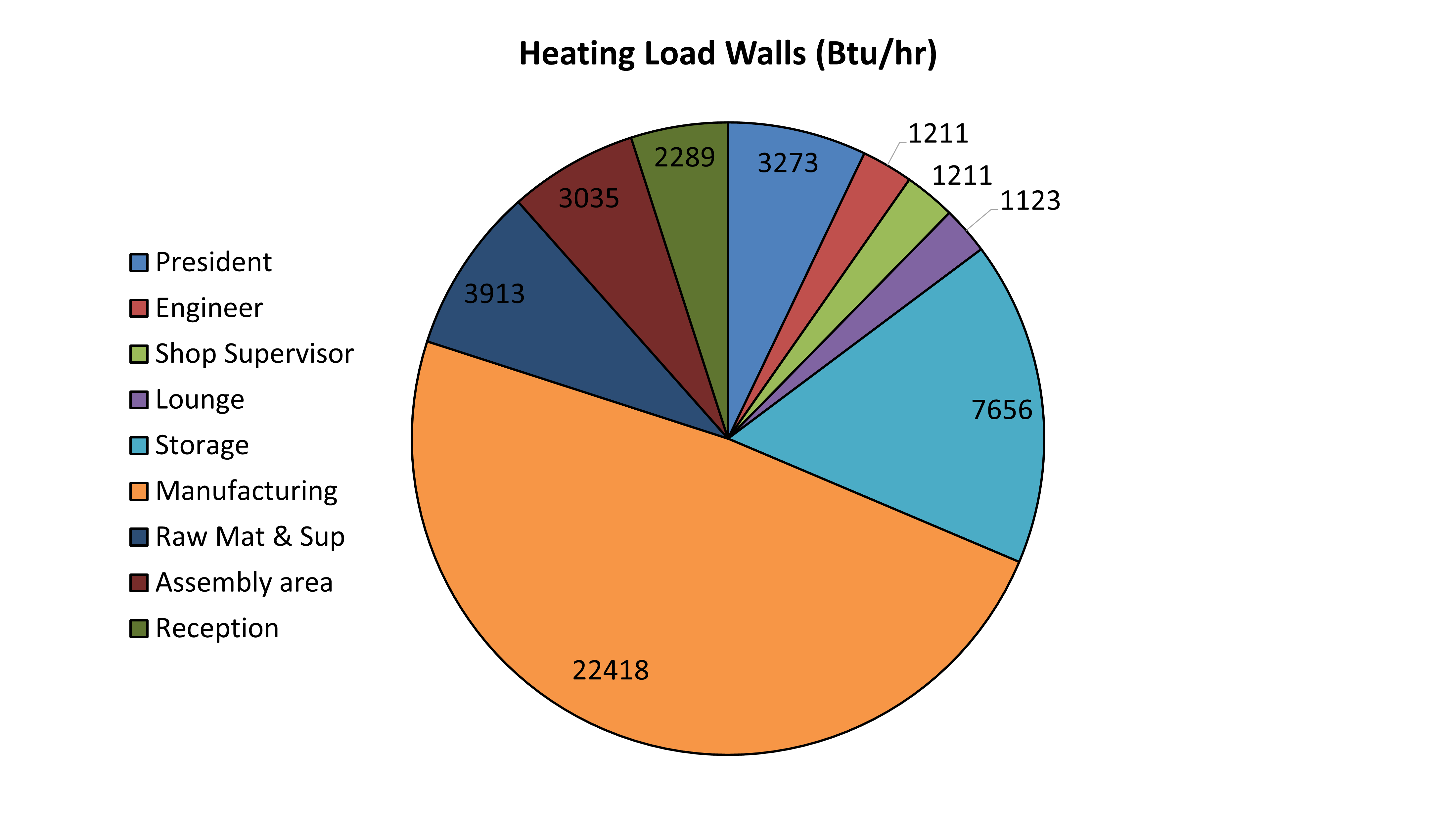

HVAC Design of a Manufacturing Building

Course Project

Designed a complete HVAC system for a small manufacturing facility in Tulsa, OK, including heating and cooling load calculations, system sizing, and duct layout design. Applied thermodynamic principles and ASHRAE standards to estimate 40-ton cooling and 117 kW heating requirements, optimizing comfort and energy efficiency through load analysis and airflow distribution.

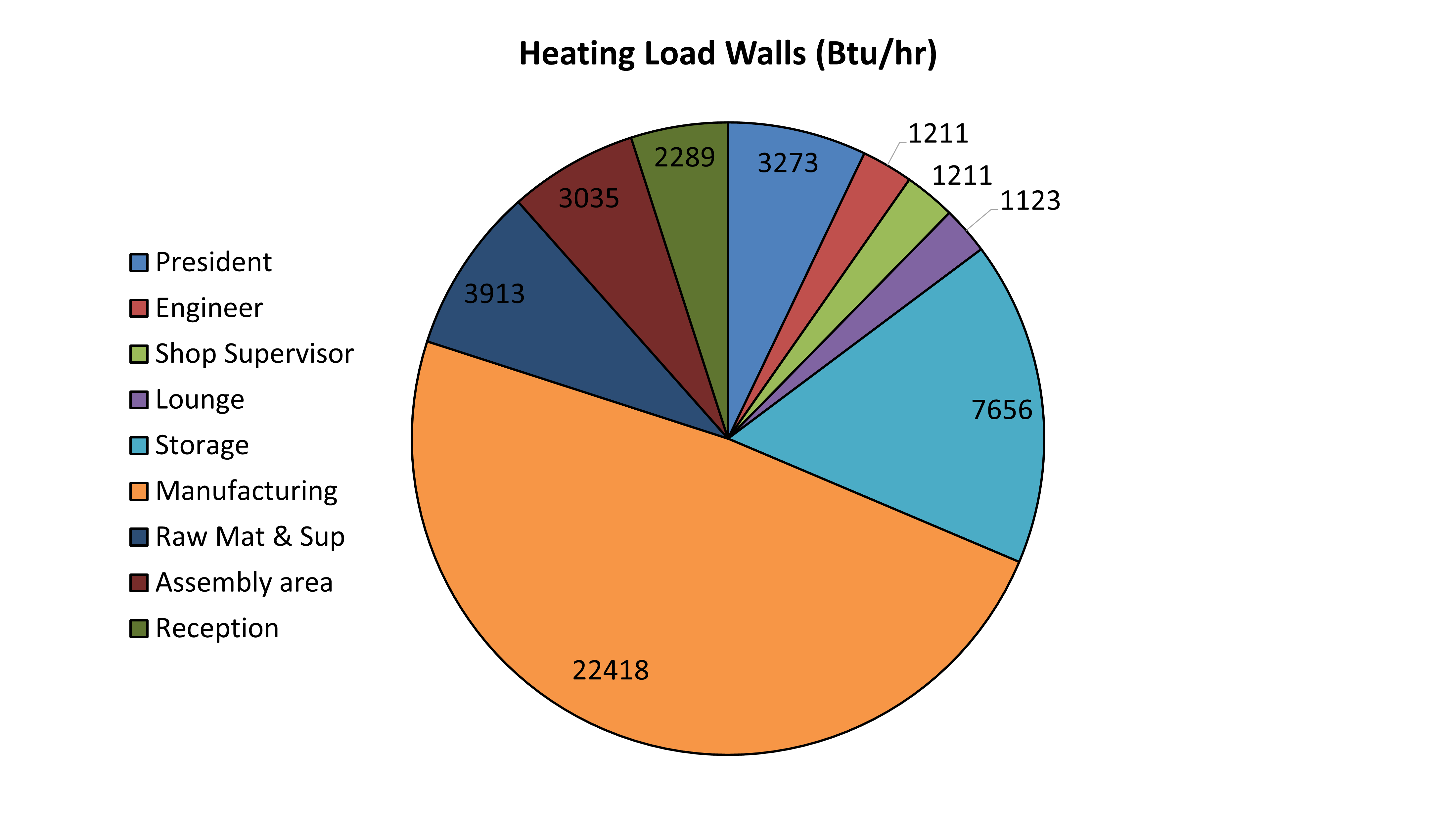

HVAC Design of a Manufacturing Building

Course Project

Designed a complete HVAC system for a small manufacturing facility in Tulsa, OK, including heating and cooling load calculations, system sizing, and duct layout design. Applied thermodynamic principles and ASHRAE standards to estimate 40-ton cooling and 117 kW heating requirements, optimizing comfort and energy efficiency through load analysis and airflow distribution.

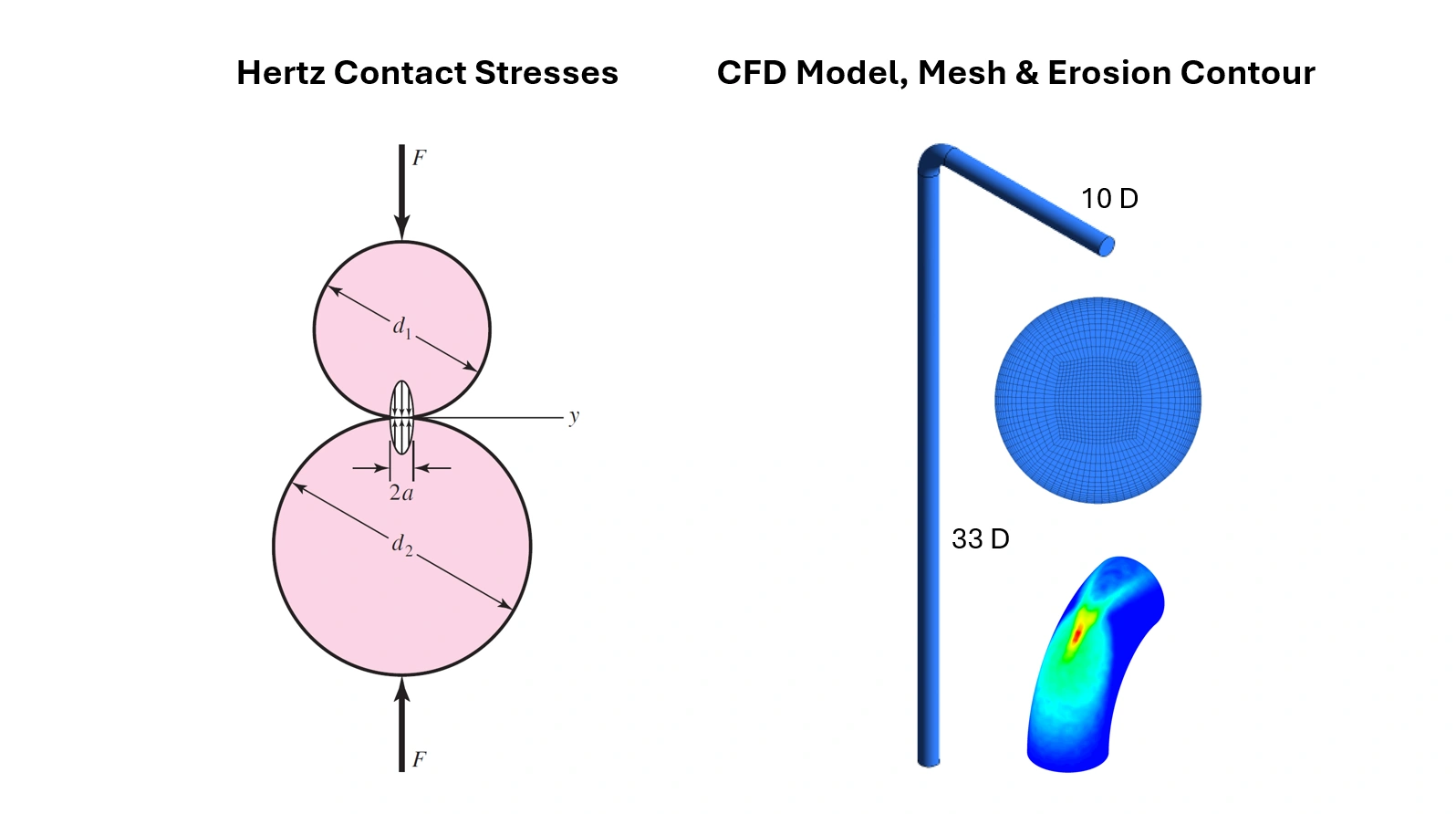

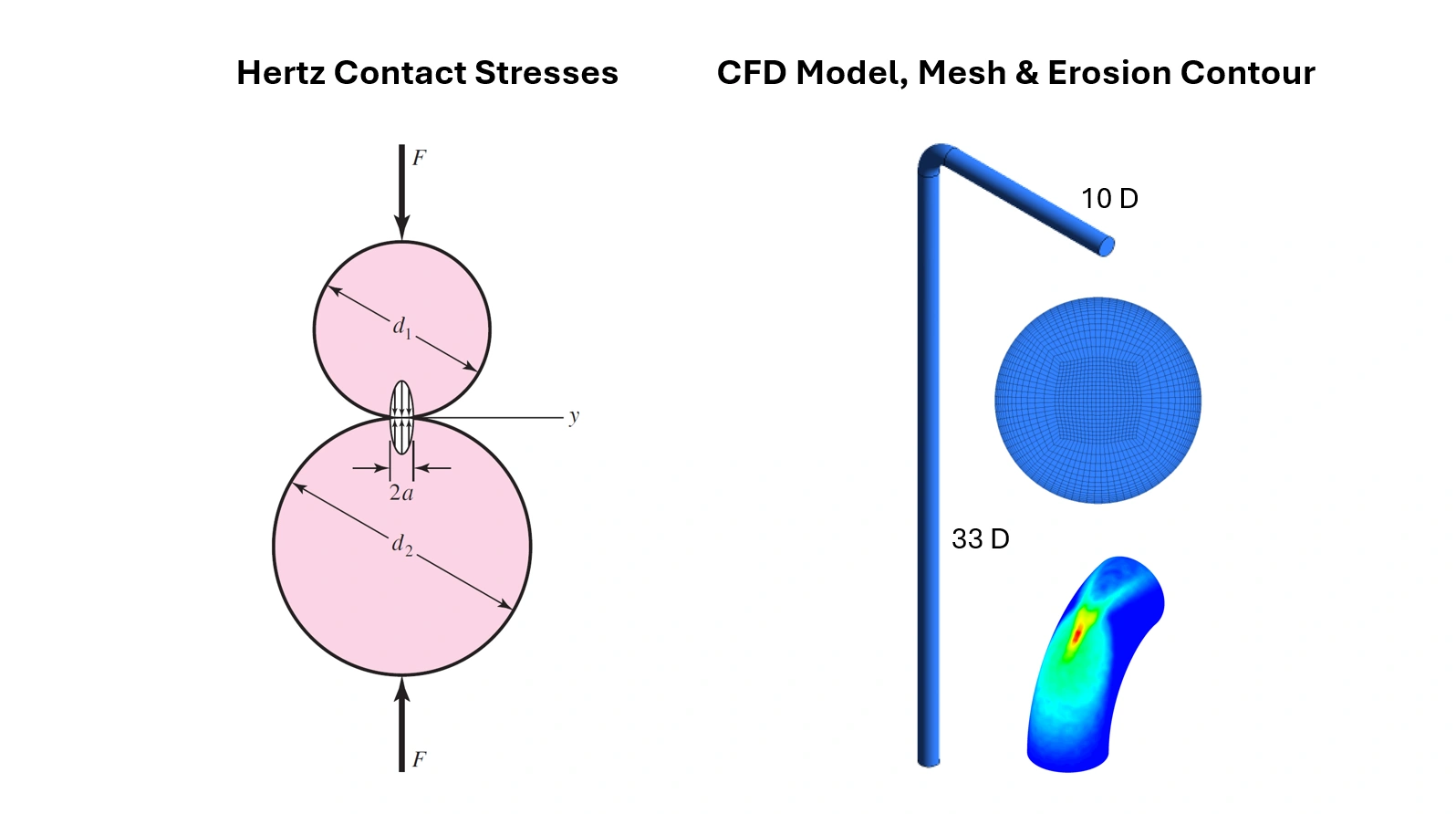

Erosion Prediction Using Hertz Stresses

Course Project

Developed a Hertzian stress based model to predict solid particle erosion in 3-inch SS316L elbows and validated it against experimental and CFD results. Integrated concepts from structural fatigue to relate impact stresses to material loss, refining model constants using Excel Solver for different particle sizes (75 µm and 300 µm).

Erosion Prediction Using Hertz Stresses

Course Project

Developed a Hertzian stress based model to predict solid particle erosion in 3-inch SS316L elbows and validated it against experimental and CFD results. Integrated concepts from structural fatigue to relate impact stresses to material loss, refining model constants using Excel Solver for different particle sizes (75 µm and 300 µm).

Skills

Awards

-

Top Performance Award

Velosi Asset Integrity and Safety, January 2021

Recognized for outstanding performance and contributions as Employee of the Month.

-

Best Paper Award

ASME Fluids Engineering Division Summer Meeting (FEDSM), July 2024

Awarded for best paper contribution and presentation in the Multiphase Flows Technical Committee (MFTC) track.

-

Honorary Graduate Returning Scholar Award

ASME Fluids Engineering Division Summer Meeting (FEDSM), July 2025

Selected based on contributions as a Graduate Student Scholar in 2024–2025. Assigned to the Multiphase Flows Technical Committee (MFTC) for continued technical engagement.

Publications

-

Experimental and Computational Fluid Dynamics Uncertainty Estimation in Solid Particle Erosion

Journal of Fluids Engineering, 2025

https://doi.org/10.1115/1.4069437 -

An Experimental and CFD Investigation Into the Effect of Solid Particle Size on Erosion in an Annular Flow

ASME Fluids Engineering Division Summer Meeting (FEDSM), 2025

https://doi.org/10.1115/FEDSM2025-158717 -

Uncertainty Analysis in Solid Particle Erosion Through Validation and Refinement of Experimental Data and Comparison With CFD

ASME Fluids Engineering Division Summer Meeting (FEDSM), 2024

https://doi.org/10.1115/FEDSM2024-131389 -

A Comprehensive Study for Defining the Uncertainty of Erosion Simulations

ASME Fluids Engineering Division Summer Meeting (FEDSM), 2024

https://doi.org/10.1115/FEDSM2024-131145 -

Effect of Pipe Size on Solid Particle Erosion of Elbow in Liquid-Solid Flow: Experimental and CFD Analysis

ASME Fluids Engineering Division Summer Meeting (FEDSM), 2024

https://doi.org/10.1115/FEDSM2024-131003 -

A Novel Technique for Determining Threshold Sand Rates from Acoustic Sand Detectors for Well Integrity Management

Society of Petroleum Engineers (SPE), 2024

https://doi.org/10.2118/222272-MS -

Evaluation of Acoustic Sand Monitors in Multiphase Flow Production for Small Sand Particle Sizes

Proceedings - Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), 2024

https://doi.org/10.2118/220727-MS